A team led by Prof. YU Shuhong, collaborating with Prof. DING Hang and Prof. WU Hengan at the University of Science and Technology of China(USTC), has revealed the fluid behavior of batch hydrothermal synthesis (BHT) by the graphene oxide (GO) aerogel and studied its influence on synthesis of nanomaterials. By using the tendency of graphene oxide (GO) to align along the flow and the fixation effect of thermoset resin, the hydrothermal annular convection can be inferred from the axisymmetric poloidal structure and GO-assembled annular distribution. The research article was published on Matter on Mar 17th.

As a 100-year-old technique, hydrothermal synthesis has been widely used and developed in synthesizing of all kinds of nanomaterials. However, batch hydrothermal reactor is known as a closed system, and what happens in this ‘‘black box’’ is mysterious. The information accessible in experiments is limited in the input raw materials, the output products, and the reaction conditions, without any knowledge of its internal workings. Understanding the heat and mass transfer is essential for better control of the batch hydrothermal synthesis. Unfortunately, pressurized tight vessels under high temperature make it difficult to study the internal workings.

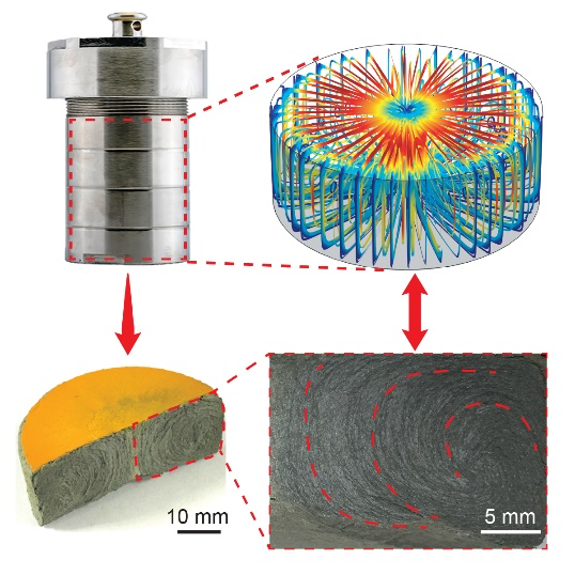

Revealing the annular convection of hydrothermal synthesis by GO-assembled gel.(Image by MA Zhiyuan et al.)

In the hydrothermal process study, the researchers found that the well-dispersed GO nanosheets can align along the flow field due to the viscous force. Taking advantage of in situ crosslinking of the thermoset resin, GO nanosheets can be fixated to generate an axisymmetric poloidal gel. The axisymmetric poloidal distribution of GO nanosheets in the obtained gel is correlated with fluid behavior in the batch hydrothermal synthesis. They also found that temperature difference and geometric symmetricity of the reactor account for the annular convection.

The researchers found that convection during hydrothermal process always exists whatever the reactor shape is. The temperature difference and size of reactor are the two main factors. Enhanced convection acts like mechanical agitation, and it would be possible to degrade the products when enlarging the hydrothermal synthesis by using a larger reactor. It is noteworthy that large-scale batch hydrothermal synthesis may not be feasible for some nanowires, nanosheets, and particularly gels due to the nonnegligible flow influence.

This research implies that the science behind the BTH process provides an inspiration for the rational utilization of BHT reaction in the future, and may also provide a new approach for the ex situ visualization technology in fluid-related research.

Paper link:

https://www.cell.com/matter/fulltext/S2590-2385(20)30077-1

(Written by LI Xiaoxi, edited by YE Zhenzhen, USTC News Center)