Metal halide perovskite (MHP) LED has become a new generation of LED devices because of its advantages such as wide color gamut, easy band gap adjustment, light-emitting half peak width and easy fabrication. The external quantum efficiency (EQE) of MHP LED already close to the level of commercial organic LED (OLED), indicating a broad application prospect of perovskite LED in lighting and display fields.

At present, perovskite LEDs are all made based on the spin-coating method, and the device area is very small (on the order of mm2), which cannot meet the commercial needs. Blade-coating is promising for fabricating large-area based on solution. However, the uncontrol crystallization process made it hard to fabricate the uniform surface.

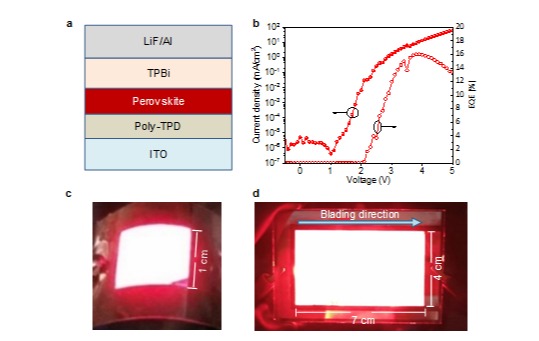

Recently, the research team, led by Prof. XIAO Zhengguo from the University of Science and Technology of China (USTC) of CAS, used sol-gel engineering of low-temperature blade-coated method to fabricate the large-area and high-efficiency perovskite LEDs. The result was published on Nature Communications.

(ultra large-area PeLED with a device area of 4X7 cm2)

The research team fabricate uniform surface through both deceasing the concentration of precursor and introducing the organoammonium halides, and the assistance of the N2 knife during the solvent evaporation. The film fabricated by this method exhibiting promising application for the high promotion on the thickness, surface roughness and lasting photoluminescence lifetime.

As one of the most important parameters of the devices, the EQE of this perovskite LEDs fabricated by blade-coating showed 16.1% when the area is 0.04cm2 and 12.7% when is 1cm2 respectively. The steady red light-emitting are showed when the area is 28cm2 under the work condition. Besides, the researchers applied this method on flexible substrate, which based on PEN/ITO, to pave the road for fabricating the large-area flexible devices.

Paper link: https://www.nature.com/articles/s41467-020-20433-4

(Written by ZHANG Liying, edited by LU Hongyu, USTC News Center)