An AI algorithm has helped researchers uncover the hidden rules of metal catalyst behaviour, offering a new roadmap for designing durable materials that drive chemical reactions.

Catalysis moves the modern world. As the foundation of the chemical industry, it contributes to a huge proportion of global production. From the Haber-Bosch process — where iron-based catalysts enable mass production of fertilizers that feed billions — to catalytic converters that reduce vehicle emissions, catalytic reactions are essential to nearly every aspect of life.

The performance of these metal catalysts, however, hinges on a long-standing scientific challenge: understanding the interface where active metal nanoparticles interact with their oxide supports, which act as a stable, ceramic-like foundation to hold the tiny metal particles in place.

This metal-support interaction (MSI), a complex interplay of atomic forces, governs the activity, selectivity and stability of heterogeneous catalysis, where the catalyst and the reacting substances are in different physical states.

“Understanding MSI is incredibly difficult,” says Weixue Li, a professor at the University of Science and Technology of China (USTC) in Hefei.

The basic rules of this interaction until recently remained a ‘black box’, he says, with the inner workings unfolding in a dynamic, multi-scale environment that is highly sensitive to the composition of metals and supports, particle size, morphology and reaction conditions.

“Our experimental tools have struggled to precisely capture the interface in situ, while theoretical calculations have been caught between accuracy and complexity,” Li adds.

Previous attempts to quantify MSI fell short, offering only partial explanations. For instance, one popular theory based on a metal’s affinity for oxygen could predict how strongly a metal might stick to an oxygen-rich surface, but it failed to explain why two different oxide surfaces, would have vastly different effects on the very same metal.

To break through these barriers, Li’s team turned to interpretable machine learning. Their approach was centered on an algorithm known as ‘sure independence screening and sparsifying operator’ (SISSO), developed by former lab member, Runhai Ouyang1.

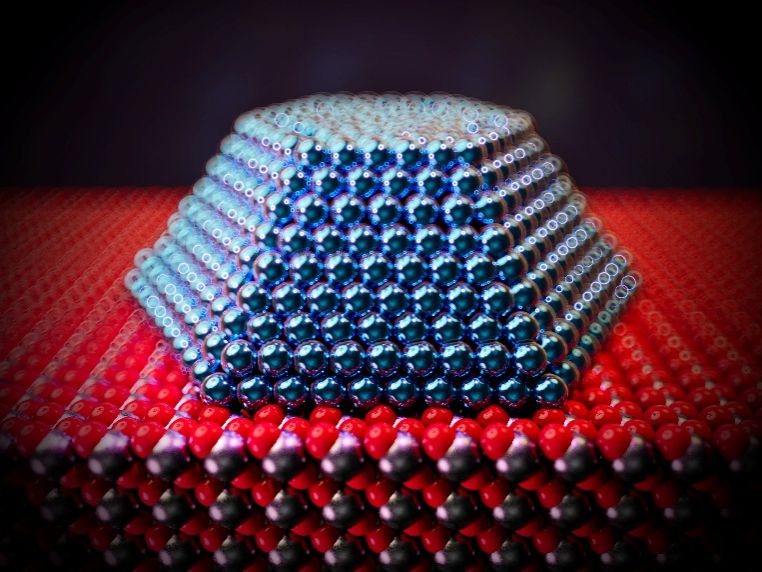

Caption: Metal nanoparticles on an oxide support — the crucial interface where catalytic reactions take place. Using interpretable machine learning, researchers in USTC have decoded the atomic-level rules governing this metal-support interaction.

Solving the puzzle

Led by PhD student, Tairan Wang, the team compiled a database of 178 pairs of experimentally measured adhesion energies — a direct measure of how strongly the metal nanoparticles stick to the oxide surface — across 25 metals and 27 oxides. To understand what atomic-level properties were driving these adhesions the researchers started with a list of 50 fundamental physical features of the metals and oxides, such as the size of the atoms, their melting points, and how readily they react with oxygen.

They then used correlation analysis to narrow the list to 14 independent variables. Based on this refined dataset and principle of parsimony, SISSO then explored a search space of more than 30 billion possible mathematical expressions to identify the underlying physical law governing MSI.

Using a compressed sensing algorithm, Li’s team identified the most concise and accurate expression for MSI prediction.

Their findings, published in Science, revealed an elegant two-part formula that pointed to two key contributors: the metal-oxygen interaction (MOI), which reflects the metal’s affinity for oxygen and determines the overall strength in forming the interface; and the metal-metal interaction (MMI), a previously underestimated factor that, particularly for late-transition metals, helps explain the influence of different supports2.

The formula represented a breakthrough in predictive accuracy. For the research team, however, prediction alone was not the ultimate goal. “The real challenge,” Li notes, “is to make the model highly interpretable, and to uncover the underlying physical principles.”

Motivated by this, Li’s team spent two years rigorously validating the formula. They started with theoretical derivations based on nearest-neighbour bonding approximation, a method to look at how atoms bond with their closest neighboring atoms. This allows a better understanding of structural behavior at the atomic scale.

They then used a combination of Density Functional Theory (DFT), a computational method for modeling electron behavior in materials, and machine learning-driven molecular dynamics simulations to test the model on real-world catalytic phenomena.

A key breakthrough came when PhD student, Jianyu Hu’s simulations reproduced the classic ‘encapsulation’ phenomenon — where oxide layers partially cover metal nanoparticles under high temperature reducing conditions, altering their surface activity.

The simulation was the final proof, showing the MMI term directly controls the speed of the encapsulation process and interfacial structure. This integration of data-driven discovery with theoretical and computational validation transformed the formula from a correlation to an explanatory physical theory, helping scientists understand why catalytic behaviour changes under different conditions.

A new rulebook for design

Armed with this new insight, Li’s team proposed a predictive principle to explain the encapsulation phenomenon.

At the atomic level, this principle describes a kind of “tug-of-war”, he says. Since the support is a metal oxide (like titanium dioxide), it contains its own metal atoms. Encapsulation is favoured when the catalyst metal (platinum, for instance) has a stronger affinity for the support’s metal atoms than the support’s metal atoms have for each other.

This simple rule explained nearly all known experimental observations of oxide encapsulation and predicted a host of new systems yet to be discovered.

For example, it could finally provide a quantitative explanation for why platinum and gold behave so differently on a titanium dioxide support — a long-standing mystery in the field. While the difference of MOIs between platinum and gold is modest, their MMIs diverge sharply, leading to different encapsulation behaviors and catalytic performances.

“We are also now much closer to the goal of designing durable catalysts on demand,” Li says. He envisions a ‘predictive-led’ workflow where engineers could screen for catalysts more effectively.

First, they could identify metals with the right oxygen affinity for a given reaction. Next, they could evaluate the MMI, to assess which metal-support combinations are likely to produce strong interactions or encapsulation, thereby enhancing catalyst stability. This enables targeted synthesis, reducing trial-and-error and increasing efficiency.

Over time, the model could evolve into a closed-loop system: as experimental results feed back into the model, predictions would continually improve. This kind of data-informed, physically grounded design process could potentially accelerate materials discovery for key industrial processes, such as CO₂ conversion, methane activation and ammonia synthesis.

The road ahead

While the current model provides a robust foundation, the team acknowledges its limitations and has a clear roadmap for the future.

Their plans include expanding the framework to non-oxide support systems, such as metal nitrides and carbon-based materials, which play key roles in next-generation catalysts. They also aim to extend the theory to sub-nano catalysts and single-atom catalysts, where interactions behave differently at the unique atomic scale.

Another priority is to study the dynamic behavior of MSI under real reaction conditions. Li’s team plans to combine in situ characterization — techniques that probe materials as reactions happen — with advanced simulations to capture how the interface evolves in the presence of adsorbates and changing temperatures.

More broadly, this work offers a blueprint for a new kind of scientific inquiry, proving that interpretable AI is not just a tool for prediction, but a partner in the quest to understand ‘why’. As Li notes, this approach is crucial in the age of AI: as technology becomes more accessible, future breakthroughs will be forged by those who pair innovative tools with a deep and patient commitment to fundamental questions.

References

1.Ouyang, R. et al. Phys. Rev. Mater. 2, 083802 (2018).

2.Wang, T. et al. Science 386, 915-920 (2024).