Superelastic and fatigue-resistant materials that can work over a wide temperature range are highly desired for diverse fields including aerospace, mechanical cushioning, energy damping, and soft robotics. Many low-density polymeric foams are highly compressible, but they often show fatigue in repeated usage and undergo superelasticity degradation near the polymers glass transition and melting temperatures.

In a recent study published in Advanced Materials, a research team led by Prof. YU Shuhong and LIANG Haiwei from University of Science and Technology of China (USTC) of the Chinese Academy of Sciences reported the thermal conversion of structural biological material, bacterial cellulose (BC), into carbon nanofiber aerogels (CNFAs) with high thermomechanical stability.

Transforming the thermally unstable structural biological materials into thermally stable graphitic materials with inherent hierarchical structure would create thermomechanically stable materials. Carbon nanotubes (CNTs) and graphene, with inherent superelasticity and thermomechanical stability, have been used recently as building blocks to prepare lightweight and superelastic materials.

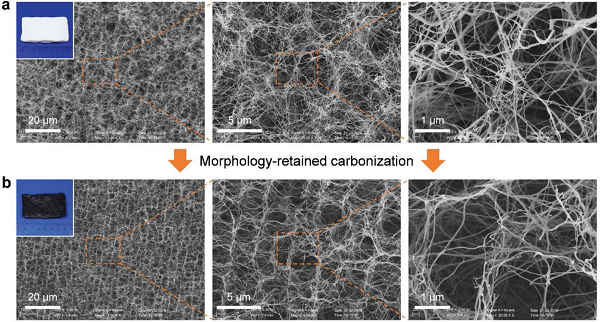

In the work, researchers realized morphology-retained carbonization of BC by engineering the pyrolysis chemistry of BC with conventional inorganic salts, and prepared CNFAs that perfectly inherit the hierarchical structures of BC from macroscopic to microscopic scales. In consequence, the prepared CNFAs exhibited exceptional temperature-invariant superelasticity and fatigue resistance over a wide temperature range at least from −100 to 500 °C.

Then they carried out electron microscopy studies to analyze the microscopic structure of BC aerogels before and after carbonization. After carbonization at high temperature, the hierarchical structure of BC was inherited perfectly in the CNFAs.

Microstructures of BC aerogels and CNFAs. (Image by Chao Li et al.)

To assess the mechanical properties of CNFAs, the researchers measured their compressive stress as a function of strain. The CNFAs were further tested at different compressive strain to assess its fatigue resistance. Further test at a compressive strain ε = 60% over T = −100–300 °Ccharacterized the temperature-invariant fatigue resistance of CNFAs. The results clearly indicated the temperature-invariant superelasticity and fatigue resistance of CNFAs over a wide temperature and strain range.

The prepared carbon aerogel perfectly inherited the hierarchical structures of bacterial cellulose from macroscopic to microscopic scales, resulting in remarkable thermomechanical properties.

This aerogel shows unique advantages over polymeric foams, metallic foams, and ceramic foams in terms of thermomechanical stability and fatigue resistance, with the realization of scalable synthesis and the economic advantage of biological materials.

(Written by LI Xiaoxi, edited by HU Dongyin,USTC News Center)