Lithium (Li) metal is one of the most attractive anode materials for next generation high energy density rechargeable batteries. However, the commercialization of Li metal batteries (LMBs) has been long term hindered by the safety issues and unsatisfied cycling performances. Replacement of liquid organic electrolytes by uninflammable solid electrolytes (SEs) could reduce the risk of catching fire and the explosion, but the electrochemical performances of LMBs based on SEs are limited due to poor rigid solid-solid electrolyte/electrode contact. A hierarchically structured solid Li metal composite anode could significantly address the interfacial issues due to the large contact area and homogenized Li+ ion flux.

To realize the merits of hierarchically structured Li composite anode with SEs, a unique hierarchical framework material has to be low cost, good rigidity, high affinity to Li and enough pore spaces. Recently, a research team led by Prof. YAO Hongbin and Prof. YU Shuhong from the University of Science and Technology of China (USTC) demonstrated a stable, dendritic free, and hierarchically structured Li metal composite anode derived from natural diatomite to realize high performance all-solid-state LMBs. This work was published on Nature Communations entitled as Diatomite derived hierarchical hybrid anode for high performance all-solid-state lithium metal batteries on June 6th (Nature Communations 2019, 10, 2482).

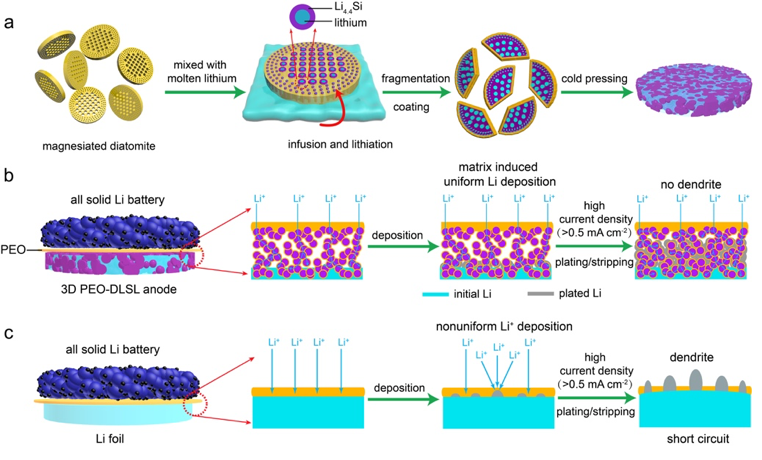

The natural diatomite is firstly transformed into hierarchical silicon framework via a magnesiothermic reduction process. Then, the diatomite derived silicon (DF-Si) powder is mixed with molten Li to yield hierarchical lithium silicide-Li hybrid fragments, which could be cold-pressed into a composite anode after the polyethylene oxide based solid polymer electrolyte (PEO-SPE) decoration. In as-fabricated PEO-SPE coated diatomite derived lithium silicide-Li (PEO-DLSL) composite anode, Li is embedded in the hierarchical pores of Li4.4Si framework and PEO coatings, resulting in high electro-active contact area to homogenize the Li+ ion flux and enable the anode integrity. This hybrid anode exhibits stable lithium stripping/plating performance over one thousand hours with average overpotential lower than 100 mV without any short circuit. Moreover, all-solid-state full cell using this lithium metal composite anode to couple with lithium iron phosphate cathode shows excellent cycling stability (0.04% capacity decay rate for 500 cycles at 0.5 C) and high rate capability (65 mAh g-1at 5 C).Therefore, the combination of hierarchical Li composite anode and SEs is a promising design to fabricate safe LMBs with high energy/power density.

The present natural diatomite derived hybrid anode will further promote the fabrication of high performance solid state Li batteries from sustainable natural resources.

It illustrates the natural diatomite derived Li metal composite anode (PEO-DLSL) fabrication process and corresponding Li stripping/plating behavior in comparison to planar Li anode.

This work was supported by National Natural Science Foundation of China, Foundation for Innovative Research Groups of the National Natural Science Foundation of China, Key Research Program of Frontier Sciences, Strategic Priority Research Program, Chinese Academy of Sciences.

see the article:https://www.nature.com/articles/s41467-019-10473-w

Written by YAO Hongbin, edited by FAN Qiong, USTC News Center.