A research team led by Prof. YU Shuhong from the University of Science and Technology of China (USTC) finds a novel way for large-scale fabrication of a family of bioinspired polymeric woods with similar polyphenol matrix materials, wood-like cellular microstructures, and outstanding comprehensive performance via a self-assembly and thermocuring process of traditional resins. This work is published on Science Advances entitled as “Bioinspired polymeric woods” on August 10th (Science Advances 2018, 4, eaat7223).

Nature has provided us with not only fantastic materials, but also inspiration for the design and fabrication of high-performance biomimetic engineering materials. Woods, which have been used for thousands of years, receive considerable attention because of their low density and high strength. The unique anisotropic cellular structure endows the woods with outstanding mechanical performances. Over recent decades, various materials have been produced into monolithic materials with anisotropically cellular structures, trying to duplicate the lightweight and high-strength woods. However, the reported artificial wood-like materials suffer from unsatisfactory mechanical properties.

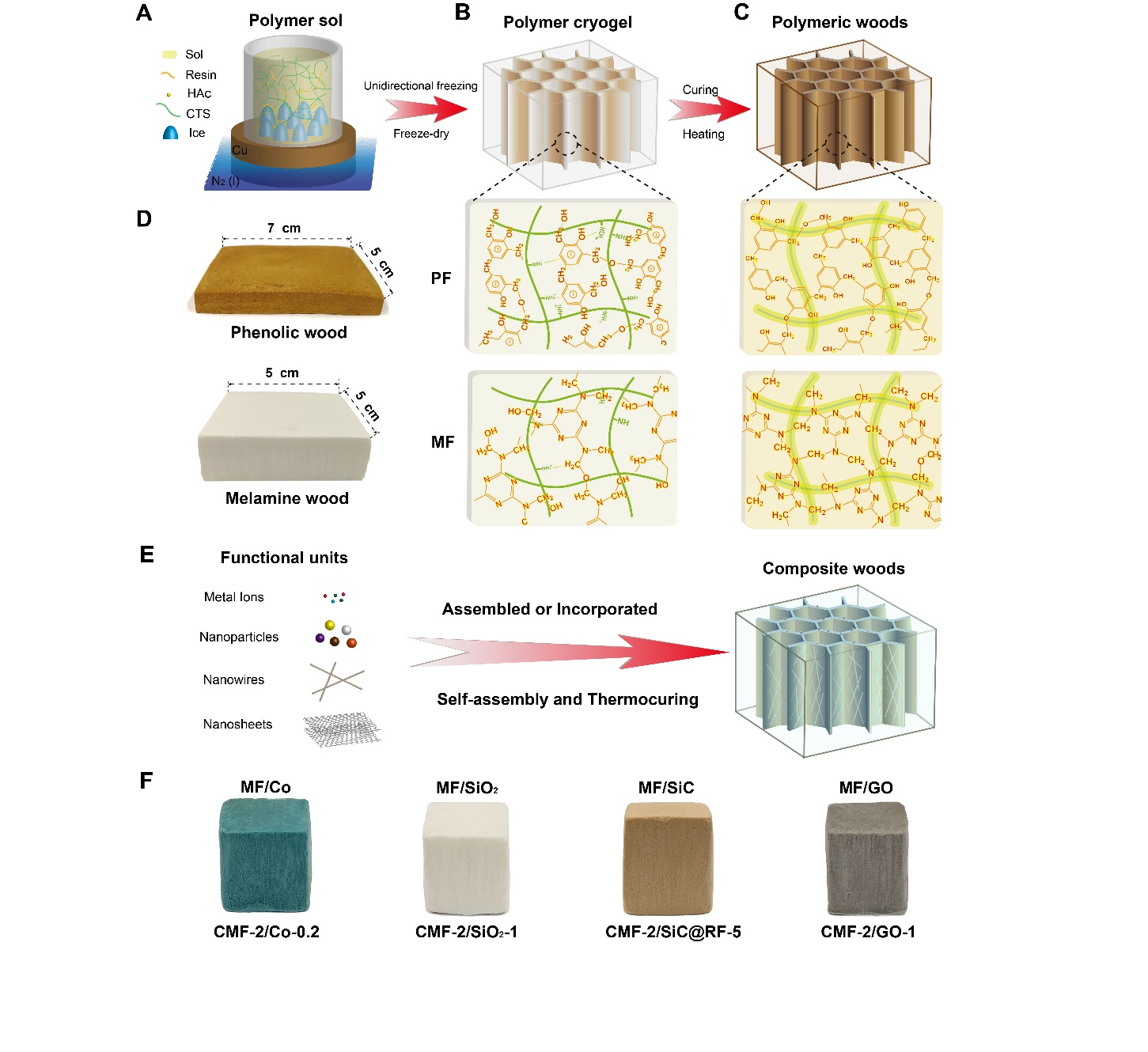

YU’s team invent a brand new method to overcome this problem. First, they unidirectionally freeze liquid thermoset resins to prepare a “green body” with the cellular structure, followed by the subsequent thermocuring to get the artificial polymeric woods. The artificial woods bear a resemblance to natural woods in the mesoscale cellular structures, and exhibit well controllability in the pore size and wall thickness. Benefiting from the starting aqueous solution, it also represents a green approach to prepare multifunctional artificial woods by compositing various nanomaterials, such as cellulose nanofibers and graphene oxide.

The polymeric and composite woods show lightweight and high-strength properties with the mechanical strength comparable to that of natural wood. In contrast with natural woods, the artificial woods exhibit better corrosion resistance to water and acid with no decrease in mechanical properties, as well as much better thermal insulation (as low as ~21 mW m^−1 K^−1) and fire retardancy. The artificial polymeric woods even stand out from other engineering materials such as cellular ceramic materials and aerogels in terms of specific strength and thermal insulation properties. As a kind of biomimetic engineering materials, this new family of bioinspired polymeric woods is supposed to replace the natural wood in harsh environments. This novel strategy provides a new and powerful route to fabricate and engineer a wide range of high-performance biomimetic engineering composite materials with desirable multifunctionality and advantages over the traditional counterparts, which will have broad applications in many technical fields.

Fabrication scheme of the bioinspired polymeric woods and kinds of composite woods based on PF and MF

This work is supported by National Natural Science Foundation of China, Foundation for Innovative Research Groups of the National Natural Science Foundation of China, Key Research Program of Frontier Sciences, Strategic Priority Research Program, National Basic Research Program of China, Fundamental Research Funds for the Central Universities, Users with Excellence and Scientific Research Grant of Hefei Science Center of CAS, National Postdoctoral Program for Innovative Talents, China Postdoctoral Science Foundation.

(Written by YU Zhilong, edited by LYU Jinghao, USTC News Center)