Assemblies with macroscopic 3D architecture from low dimensional nanomaterials are showing increasing significance, much effort has been devoted to the hierarchical organization of one dimensional (1D) nanomaterials into serviceable macroscopic assemblies. However, how to efficiently assemble 1D nanoscale building blocks into advanced hierarchical structures is still a challenge. To address this, YU Shuhong and his team recently proposed a general and efficient assembly strategy to assemble versatile 1D nanomaterials with large-scale and good controllability, using ice as template. This work has been published in Angew. Chem. Int. Ed. (Angew. Chem.-Int. Ed. 2014, 53(18), 4561-4566) and highlighted by Materials Views (http://www.materialsviews.com/ice-templating-makes-flexible-stretchable-conductors/).

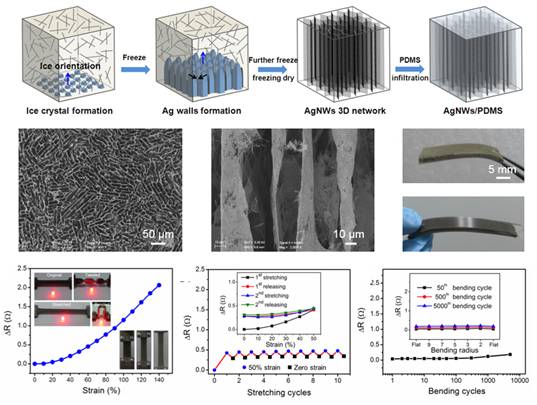

Fig. 1 (a) Schematic showing the formation mechanism of the compartmental monolith by freeze casting. (b, c) Typical top-view and side-view SEM images of AgNWs networks. (d, e) Photos of the 3D AgNW monolith and AgNWs/PDMS composite. (f) ΔR of the composite as a function of uniaxial tensile strain until fracture. Left inset: photographs of the device for lightening a commercial LED using the AgNWs/PDMS composites. Right inset: photographs of the stretching process. (g) ΔR of a composite after 50% stretching and then releasing for each cycle with the same stretching rate of 1 mm min-1. Inset: the ΔR of the composite as a function of tensile strain up to 50% in the first two stretch-release cycles. (h) ΔR as a function of the bend cycles at a maximum bend radius of 2.0 mm. Inset: the fiftieth, five hundredth, five thousandth bending cycles.

Using their new method, Yu’s team successfully assembled 1D silver nanowires (AgNW) into serviceable macroscopic assemblieswith fascinating 3D hierarchical architecture. Furthermore, by regulating the influence factors to the process of ice growth, they took control of the microstructure of the macroscopic assemblies. They found that the unique microstructure of the 3D AgNW assemblies provided it with remarkable electrical conductivity and electromechanical stability.

As a potential application, Yu’s team made stretchable and foldable conductors, and excellent performance was demonstrated. The composite remained conductive with a resistance change of only about 2 Ω until it broke at 140% strain. The resistance of the AgNWs/PDMS composite increased with increasing tensile strain during the first cycle of stretching, while it became nearly stable from the second stretch-release cycle. The irreversible resistance increase was only about 0.3 Ω under 50% stretching, and became larger for a larger tensile strain. Even after one thousandth stretch-release cycles the AgNWs/PDMS composites did not show obvious irreversible resistance increase. These results can be reasonably attributed to the partial irreversible separation between the AgNWs in the network.The resistance showed a slight increase of less than 0.1 Ω at a bending radius of 2.0 mm during the first bending cycle, and almost entirely recovered after straightening. Even after 5,000 cycles with a bend radius of 2.0 mm, the resistance variation of composites was just less than 0.2 Ω. These results show a good proof of the excellent electromechanical stability of AgNWs/PDMS composites and their great potential for high-performance stretchable and flexible conductors. The tunability of the network structure together with the outstanding electrical properties should make the macroscopic 3D AgNW architectures and their composites suitable candidates in electronic applications.

The research project is sponsored by the National Basic Research Program of China, the National Natural Science Foundation of China and the Chinese Academy of Sciences.

Link to the paper: http://onlinelibrary.wiley.com/doi/10.1002/anie.201400457/abstract

(By GAO Huailing, HFNL)