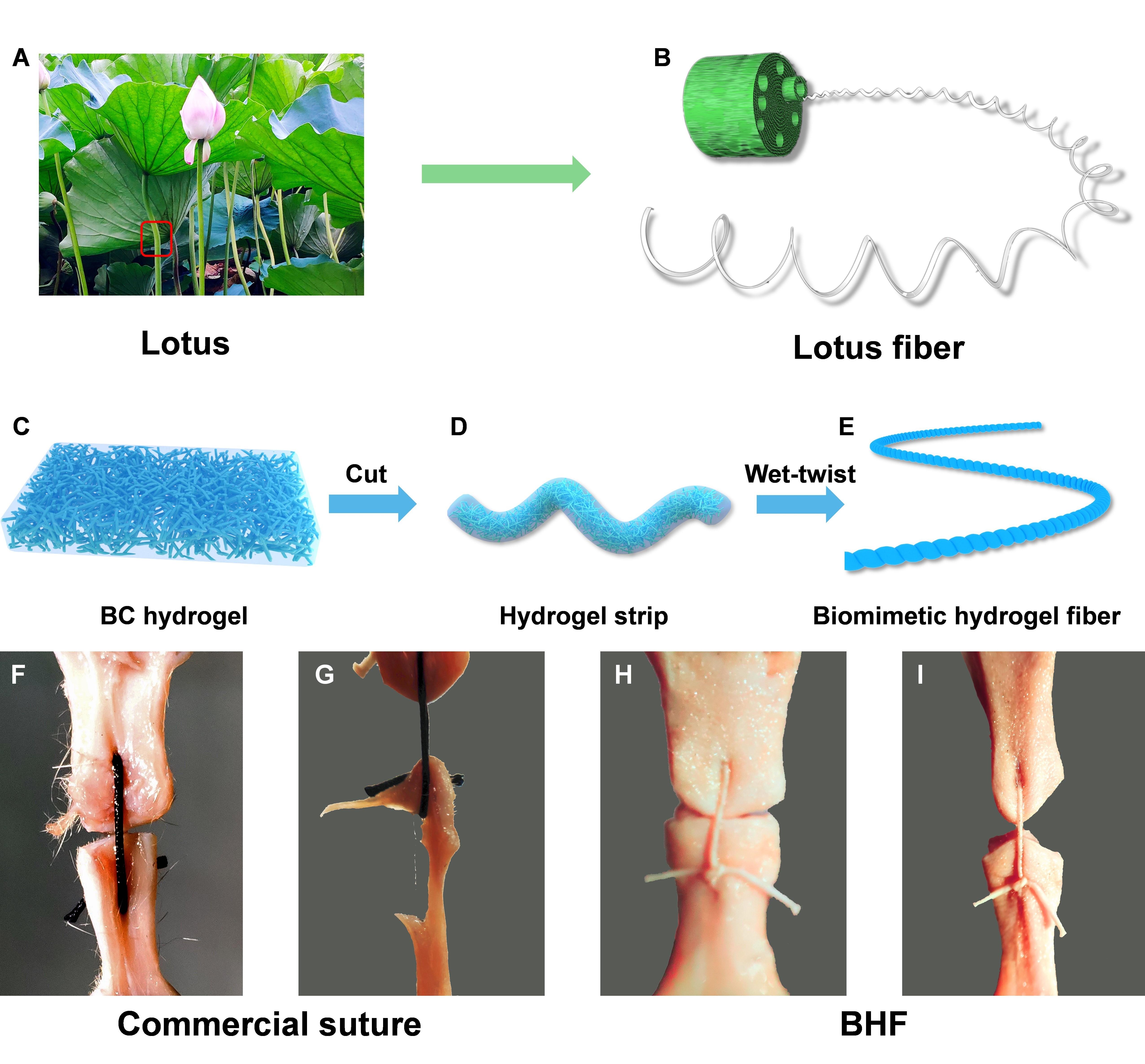

"The lotus roots may break, but the fiber remains joined" is an old Chinese saying that reflects the unique structure and mechanical properties of the lotus fiber. The outstanding mechanical properties of lotus fibers can be attributed to their unique spiral structure, which provides an attractive model for biomimetic design of artificial fibers.

In a new study published in Nano Letters, a team led by Prof. YU Shuhong from the University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS) reported a bio-inspired lotus-fiber-mimetic spiral structure bacterial cellulose (BC) hydrogel fiber with high strength, high toughness, excellent biocompatibility, good stretchability, and high energy dissipation.

Unlike polymer-based hydrogel, the newly designed biomimetic hydrogel fiber (BHF) is based on the BC hydrogel with 3D cellulose nanofiber networks produced by bacteria. The cellulose nanofibers provide the reversible hydrogen bonding network that results in unique mechanical properties.

The researchers applied a constant tangential force to the pretreated BC hydrogel along the cross-sectional direction. Then, the two sides of the hydrogel were subjected to opposite tangential forces, and local plastic deformation occurred.

The hydrogen bonds in the 3D network of cellulose nanofibers were broken by the tangential force, causing the hydrogel strip to twist spirally and the network to slip and deform. When the tangential force was removed, the hydrogen bonds reformed between the nanofibers, and the spiral structure of the fiber was fixed.

Benefited from lotus-fiber-mimetic spiral structure, the toughness of BHF can reach ~116.3 MJ m-3, which is more than nine times higher than those of non-spiralized BC hydrogel fiber. Besides, once the BHF is stretched, it is nearly non-resilient.

Combining outstanding mechanical properties with excellent biocompatibility derived from BC, BHF is a promising hydrogel fiber for biomedical material, especially for surgical suture, a commonly used structural biomedical material for wound repair.

Compared with commercial surgical suture with higher modulus, the BHF has similar modulus and strength to soft tissue, like skin. The outstanding stretchability and energy dissipation of BHF allow it to absorb energy from the tissue deformation around a wound and effectively protect the wound from rupture, which makes BHF an ideal surgical suture.

What's more, the porous structure of BHF also allows it to adsorb functional small molecules, such as antibiotics or anti-inflammatory compounds, and sustainably release them on wounds. With an appropriate design, BHF would be a powerful platform for many medical applications.

Fabrication, structure analysis, and in vitro biomechanical experiment of biomimetic hydrogel fiber (BHF).

Paper link:

https://pubs.acs.org/doi/10.1021/acs.nanolett.0c03707

(Edited by JIANG Pengcen, USTC News Center)