A research team led by Associate Professor LI Mujun, Professor ZHANG Shiwu, and Professor HU Bing from the University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS) developed porous magnetic soft grippers (PMSGs) that can gently and quickly grasp delicate living things. They can handle a variety of objects, from thin wires to fragile organisms, and have potential applications in biomedicine and scientific research. Their findings were published in Advanced Materials.

Manipulating living objects requires grippers that can adapt to different shapes and exert enough force without causing harm. Hence, soft grippers are better than traditional rigid ones as they offer more flexibility. As one type of the soft grippers, magnetically driven grippers have advantages like rapid response and wireless control, but existing designs often compromise between shape adaptability and payload capacity.

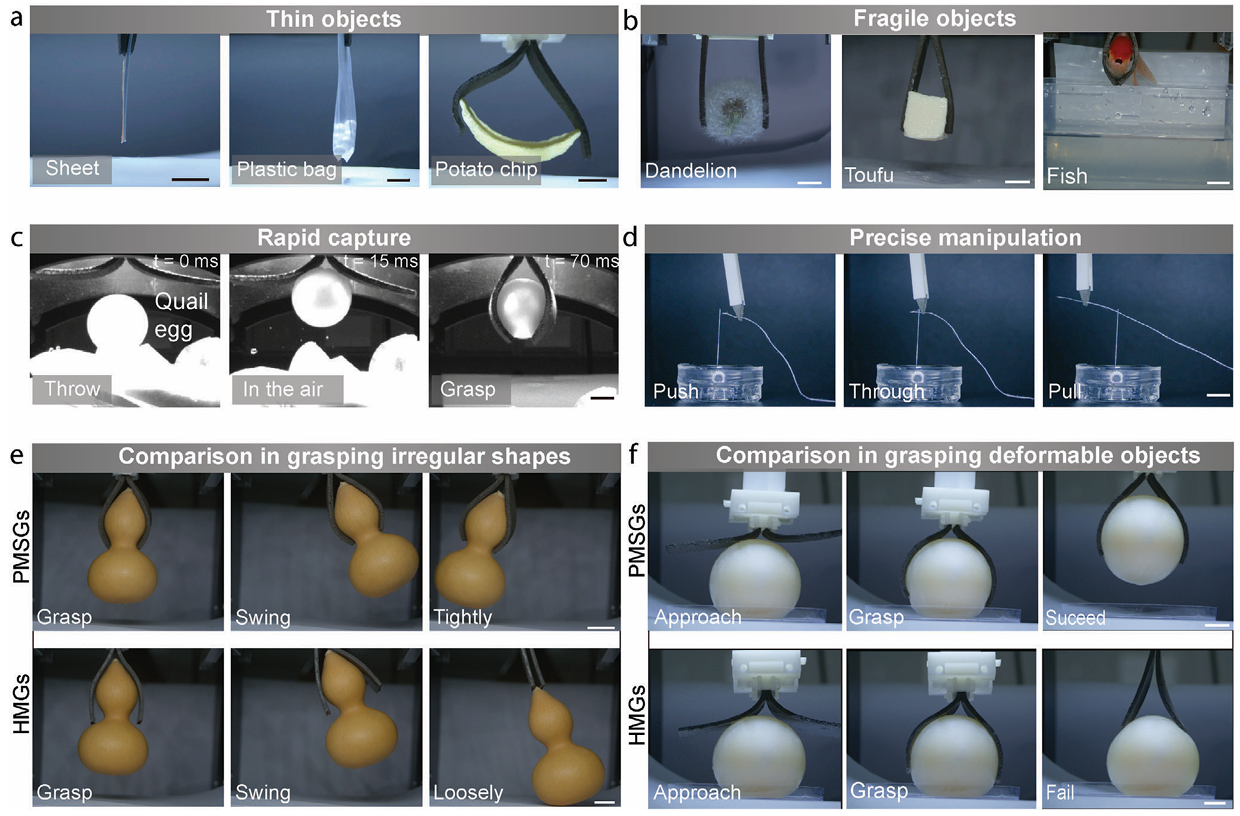

To solve this problem, the researchers introduced a porous structure into the magnetic silicone elastomer. The porous structure within the grippers offers a way to tune the elastic modulus of the materials and make them more lightweight, soft, and flexible. The porous design also increased the gripper's deformation ability and provided a substantial buffering potential, reducing the impact on gripped objects.

Specifically, the traditional way to increase the gripping force of a gripper is to increase the content of magnetic powder. However, the more magnetic powder there is, the gripper will become stiffer and its gripping ability will decrease. In order to make the gripper maintain both high gripping force and softness, the researchers proposed to "subtract" in structure —— to create pores in the magnetic silicone. However, achieving a balance between high magnetic powder content and a large porosity is an extremely challenging task.

After having tried numerous pore-forming methods, the team finally selected the solid template decomposition pore-forming method, which uses decomposable solid materials to form the required pores. The team applied NH5CO3 as a pore-forming agent, which decomposes into gases during heating, thus enabling the formation of a rich pore structure in the gripper with a high magnetic powder content.

By introducing a porous structure to replace part of the silicone, the team not only increased the magnetic driving force of the gripper, but also improved the flexible wrapping ability of the gripper. This dual improvement significantly enhanced the gripper's ability to grip heavy objects, providing a more reliable gripping solution than traditional mechanical grippers.

Demonstration of Versatility in PMSGs. Scale bar = 10 mm. (Image by USTC)

The development of PMSGs represents a significant advancement in gripper technology. By integrating a porous structure into a magnetic silicone elastomer, the researchers have overcome the trade-off between shape adaptability and payload capacity. The grippers' ability to gently and quickly grasp delicate living objects has potential applications in biomedical and scientific fields, opening up new possibilities for the manipulation of delicate organisms.

Paper link: https://doi.org/10.1002/adma.202409173

(Written by CHEN Yehong, Edited by WU Yuyang, USTC News Center)